Ceramic Filters: Understanding Their Function and Operation

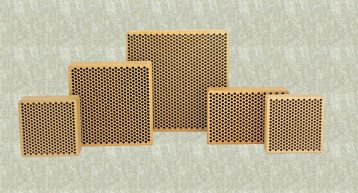

Ceramic filters in foundry operations are used for molten metal filtration to remove impurities and improve the quality of castings. These filters are typically made of porous ceramic materials and come in various shapes and sizes. They are mainly made of aluminum oxide or silicon carbide they have immense thermal and chemical resistance and the tiny pores on the ceramic filters are their main characteristic as they enable the passage of fluids by efficiently filtering and removing unwanted particles for a defect-free and flawless casting with a perfect finish.

Some keynote features of Ceramic Filters make them the best for filtration let’s see how they work to deliver the best results in the industrial process and foundry industry.

- Porous structure: Ceramic filters are manufactured with highly porous structures that consist of interconnected channels and voids

- Size Exclusions- The prime mechanism that works in ceramic filters is the size of pores which restrit’s the flow of larger particles in the fluid it is smaller than the particles for a lustrous contamination-free fluid to flow.

- Deep filtration: The main focus of a ceramic filter is deep filtration through the multiple layers of porous structure which allows particles to stay on the surface itself.

- Temperature & heat resistance – The use of ceramic filters is mainly done in industries that include operations of chemical treatments and immense temperatures and ceramic filters are made in a way to withstand any kind of harsh treatments without any degradations.

APPLICATION & USES

CERAMIC FILTERS ARE WIDELY USED IN INDUSTRIES WHERE EXCEPTIONAL FILTRATION IS REQUIRED FOR A SMOOTH & EVEN CASTING RESULT

METAL CASTING- METAL CASTING IS A VERY INTRICATE PROCESS IN WHICH THE MOLTEN METAL HAS TO BE POURED IN THE MOLD WITHOUT ANY KIND OF CONTAMINATION, CERAMIC FILTERS HELP TO FORM A DEFECT-FREE CASTING.

WATER FILTERS- A VERY CRUCIAL PART OF WATER FILTRATION IS CERAMIC FILTERS AS THEY HELP TO PURIFY THE BACTERIA, SEDIMENTS, POLLUTANTS, IMPURITIES, AND OTHER SOLID IMPURITIES FROM DRINKING WATER.

CHEMICAL PROCESSING- CHEMICAL PROCESSES HAVE A VERY FINE FILTRATION TO PURIFY THE LIQUIDS AND SOLID CHEMICALS AND THUS CERAMIC FILTERS ARE BEST FOR THAT.

AVIATION INDUSTRY- FOR HIGH END PERFORMANCE OF AN ENGINE AND AIRCRAFT CERAMIC FILTERS ARE USED TO FILTERING THE LUBRICATING OILS.

SS KHARDEKAR INDIA PVT LTD are the dominant manufacturers and suppliers of ceramic filters which suit for any industrial process, they have a qualitative as well as technical approach to deliver the best products in the foundry and casting industry.

In Co-operation with company Lanik Ceramic Foam Filters India Pvt. Ltd. & Keramtech s.r.o; they are supplying ceramic foam filters (VUKOPOR) & ceramic filters respectively.

They are soon turning to be pioneers in the foundry industry.