S. S. KHARDEKAR INDIA PVT. LTD.

VUKOPOR® HT – Zirconia Filters

DESCRIPTION :

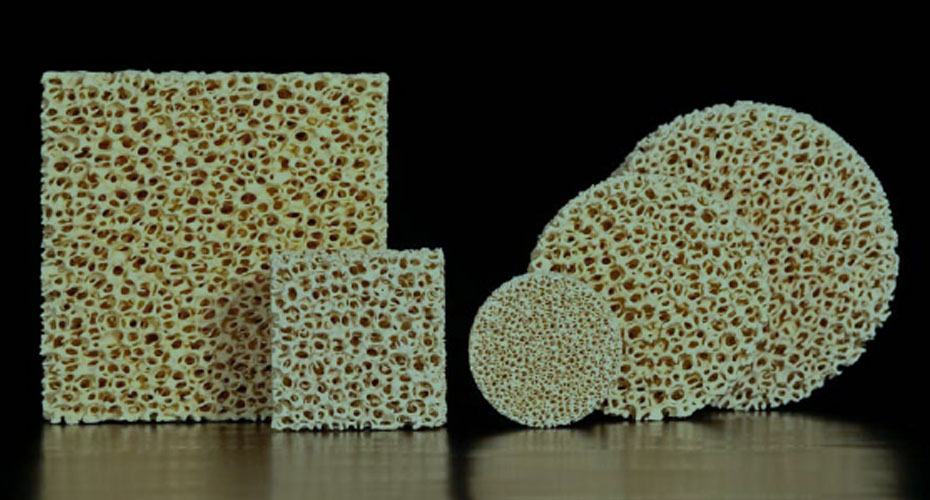

VUKOPOR® HT ceramic foam filters are determined for filtering of steel and steel alloys up to the temperature of 1700 °C. Filters are recommended especially for high quality grades of alloys.

VUKOPOR® HT ceramic foam filters are made of ceramics on the basis of partially stabilized ZrO2. The filter body has a typical robust ceramic construction and excellent thermo-mechanical properties providing the filter with an outstanding stability in operation.

The typical feature of the filter structure is the three- dimensional network of opened pores forming a labyrinth of its ceramic body. Therefore, all the mechanisms of efficient filtration can be used and calm mould filling is possible.

The homogenous structure of the filters with a minimum of blocked pores inside provides an optimal utilization of total filter capacity and an equal pouring speed within filtering.

RECOMMENDED APPLICATION :

VUKOPOR® HT filters can be used in gating systems by different ways. It may be used directly in the gating system in special filter prints, inside the ceramic shell or ceramic cups (e.g. investment casting).

It is necessary to take into consideration high thermal capacity of zirconium filters and their suitability for different alloys filtration at their usage in exothermic sleeves or pouring basins (direct pouring on filter).

The perfect stability and high mechanical resistance allow the utilization of filters inside the Filter Carousels and Filter Lanes and thus filtering of heavy castings of several dozens of tons is enabled.

Ceramic foam filters generally help to produce higher quality castings at lower production costs.

ENHANCED QUALITY OF CASTINGS :

- Better quality of casting surface.

- Improved mechanical properties of castings.

- Improved precision of dimensions and shapes of castings.

COSTS REDUCTION :

- Reduced amount of scrap.

- Reduced costs of finishing operations.

- Simpler design and gating system.

TECHNICAL SPECIFICATION

|

Chemical Composition: |

partially stabilized ZrO2 |

|---|---|

|

Bond: |

ceramic |

|

Colour: |

ochre to orange |

|

Application Temperature: |

max. 1 700 °C |

|

Porosity: |

10, 15, 20 ppi |

|

Basic Shapes: |

square, circle, rectangle, cone frustum |

|

Special Improvements: |

sealing gasket cf.g. 3 or 6,4 mm |

|

Tolerance of Dimensions: Note: measured with callipers equipped with flat contact elements (46x30 mm) |

+ 0,5 / - 1,5 mm (up to 99 mm) + 0,5 / - 2,5 mm (above 100 mm) |

RECOMMENDED APPLICATION

VUKOPOR® HT filters can be used in gating systems by different ways. It may be used directly in the gating system in special filter prints, inside the ceramic shell or ceramic cups (e.g. investment casting).

Closed pores, cracks and holes in the effective areas of the filter are not allowed. The surface area of the sidewalls can be filled with ceramics.

DIMENSIONS AND TECHNICAL PARAMETERS

The values shown in the table below are based on so-far performed tests and information available. They can vary depending on the actual conditions in foundries e.g. temperature, metal contamination level, filter position in gating system and other variables.

When choosing a size, shape, dimensions and porosity of a filter, you should keep to the generally applicable rules and principles. The same applies to choosing the type of the “filter print”, space for the filter placement and its orientation.

The basic rules and recommendations are given in the Application List “How to design gating system with filters”. Atypical applications should be consulted with the Sales Department.

|

Dimension (mm) |

Thickness (mm) |

Pouring Rate (kg/s) |

Total Capacity (kg) |

|

| Carbon Steel | High-Alloyed Steel | |||

|

40x40x |

18, 20, 22 |

1,5 |

2 |

35 |

|

50x50x |

20, 22, 25 |

2 |

3 |

55 |

|

55x55x |

20, 22, 25 |

2,5 |

3,5 |

65 |

|

60x60x |

22, 25 |

3 |

4 |

80 |

|

75x50x |

22, 25 |

3 |

4 |

85 |

|

75x75x |

22, 25 |

4,5 |

7 |

120 |

|

100x75x |

22, 25 |

6 |

8 |

160 |

|

100x100x |

22, 25, 30 |

8 |

10,5 |

220 |

|

125x125x |

22, 25, 30 |

12,5 |

16 |

340 |

|

150x150x |

25, 30, 38 |

18 |

23 |

490 |

|

ø 50x |

22, 25 |

1,5 |

2,5 |

50 |

|

ø 60x |

22, 25 |

2 |

3,5 |

70 |

|

ø 70x |

22, 25 |

3 |

4,5 |

90 |

|

ø 75x |

22, 25 |

3,5 |

5,5 |

110 |

|

ø 85x |

22, 25 |

4,5 |

6 |

130 |

|

ø 90x |

22, 25 |

5 |

7,5 |

150 |

|

ø 100x |

25, 30 |

6,5 |

9,5 |

180 |

|

ø 125x |

25, 30 |

9 |

12 |

280 |

|

ø 150x |

25, 30, 38 |

13 |

17 |

400 |

PACKAGING AND MARKING

The foundry filters are packed in cardboard boxes protecting them from damage. Layers of filters are separated with a soft tissue. Space is left between individual filters to prevent contact in the box. The box with filters must be delivered undamaged without apparent defects. Each box has a filter identification tag containing data on: filter type, porosity, dimension, production date, production order number, number of the inspection worker, additional label, etc.

HANDLING AND USE

Ceramic foam filters are fragile and should be handled accordingly. Take a filter out of the package and carefully remove possible ceramic particles by hand or blow them off with pressure air. It is recommended to handle foundry filters without gloves.

By no means try to adapt the filter (cutting or grinding). Its shape and dimensions must correspond with the space in the filter print or ceramic shell. For this purpose filters can be protected with a sealing gasket or with a taper for correct position in conical inlets.

TRANSPORTATION AND STORING

The cardboard boxes and packages with ceramic foam filters are transported in covered means of transport. They can only be stored in covered and dry storage rooms. It is only allowed to stack seven layers on each other. If during the transport the filters were exposed to high humidity, they have to be dried at the temperature of 110 oC until completely dry before use.

QUALITY CONTROL PROCESS

The ceramic foam filters are manufactured in compliance with the quality control standards ISO 9001 : 2008.