USE OF CERAMIC FOAM FILTERS

Casting is a process the founding industry which requires high level of precision, perfection , patience to achieve the desired size shape and quality. It is obvious that metal casting process needs perfect skill and perfect components but then too some impurities are present in the molten metal which may way to the casting and thus, can effect the quality as well as required and desired shape. So the major foundries use ceramic foam filters for a neat, dust free and flawless casting of metals.

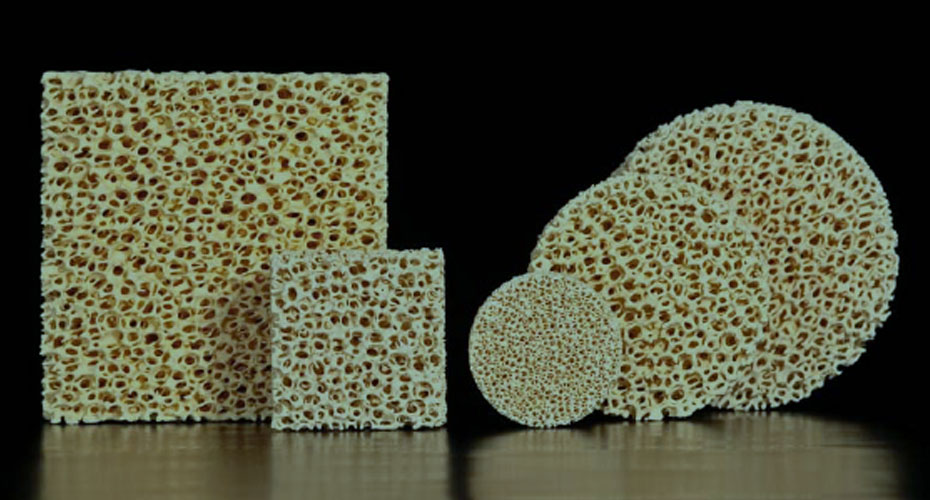

Ceramic foam filters are porous structures made of ceramic materials that are used in various industrial applications, particularly in the metal casting industry. These filters are designed to remove impurities and solid particles from molten metal before it is cast into a final product.

SS Khardekar India pvt Ltd being one of the most experienced and reputed supplier of a wide range of products like Ceramic Cups, Ceramic Foam Filters, Ceramic Cores, Kore Stick.

As an ace manufacturer and suppliers of foundry products they have established a strong name in the market.

The best name in ceramic foam filters is undoubtedly in association with Lanik Ceramic foam filters that are designed for the castings from steel alloys, metal alloys or any kind of alloys.

Ceramic foam filters both are efficient in giving the cleanest, filtered, dust free mixture of molten metal. Ceramic filters have humongous properties, let’s see how they help in creating a easy process of metal casting.

• Filtration & Fluidity:– Non-metallic impurities, slags or oxides or any other impurity entering during the pouring is effectively filtered for a hassle free pouring of molten metal. It is assured that along with filtration the fluidity is also enhanced while pouring the molten metal.

• Structure & material- The materials and structure both are made in a way to get smooth casting without any impurities.

• Environment friendly:- Ceramic foam filters are completely eco-friendly and ensure that they are made with natural and organic materials, as they are produced with no defects there is no rejection or wastage of product and due to these filters the emissions of green house gases and other harmful gases is also obstructed. It is made sure that sustainability is the major objective during the process of casting.

• Application, size & shapes- Ceramic foam filters are mainly used in metal casting, die casting, foundries, automotive industries as they prevent a turbulent free flow and are available in many sizes and shapes( round, square) to accommodate all kinds of casting set-ups.

• Heat insulation:- The ceramic foam filters enable to maintain the temperature and ensure that the molten metal stays in its liquid state until it’s poured sufficiently in mold cavity. The temperature helps the reduction of gas defects and avoids the gas bubbles to form and allows the molten metal to solidify with uniformity to acquire the perfect shape of casting.

• Assembling & Maintenance:- Ceramic foam filters are easy to set up and foundries can easily install them or place the filters in gating systems or pour basins for efficiency in filtering the impurity before it enters mold cavity. Once the ceramic filters stop filtering the impurities they have to be replaced with new ones.

SS Khardekar India pvt Ltd are the pioneers in the foundry industry and keep an entire requirement of any kind of ceramic filter in any desired shape for a perfect casting of iron without any impurities.