S. S. KHARDEKAR INDIA PVT. LTD.

SS Khardekar India pvt Ltd is one the most popular supplier and manufacturer when it comes to foundry and casting industries, their all products are ISO certified and experience in a very short time. They have built their goodwill as superior quality Manufacturer and Suppliers of Insulating, Exothermic, High...

Introduction of Insulating Sleeves: Insulating sleeve is a very high temperature resistant tube commonly used as thermal protection for wires, cables, and hoses that are constantly exposed to very high temperature environments such as engines, exhaust system. An insulating sleeves looks like a tube or cylindrical and are chrome...

Exothermic sleeves are a crucial and a very essential part of foundry industries. They enable high performance to feed castings in iron, steel and all the alloys of these metals, molded in sand and other systems. They are inbuilt with thermal insulation to maintain desired temperature for an accurate...

Introduction: In the rapid world of industrialization and competition in all the sectors, precision, perfection and safety are the key elements for any industry to sustain. Right from the raw materials, equipments, machineries, has to be accurate and effortless to give a desired result of the product. Mould sealing...

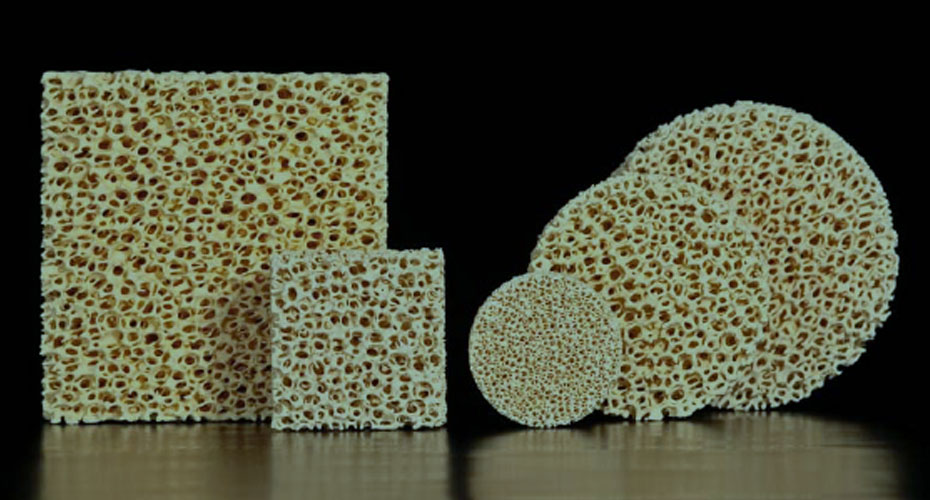

Casting is a process the founding industry which requires high level of precision, perfection , patience to achieve the desired size shape and quality. It is obvious that metal casting process needs perfect skill and perfect components but then too some impurities are present in the molten metal which...

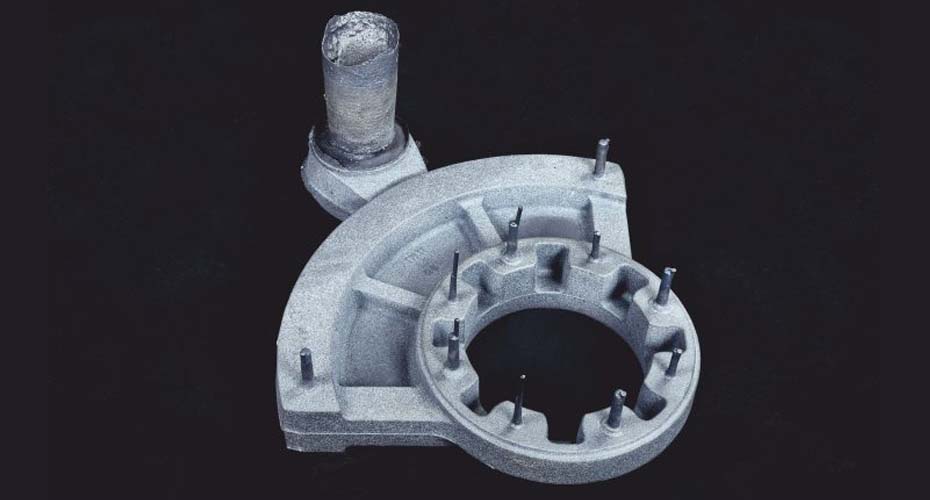

INTRODUCTION A factory that produces metal castings is known as a foundry. Basically metals are melted and casted into different shapes and desired sizes. Casting is a very crucial and critical process which needs a lot of perfection and precision to acquire the exact result and thus, Exothermic sleeves...

Introduction and Meaning : The direct pour system, also known as the direct pouring method or bottom pouring system, is a modern approach to the metal casting process. The success of industries like automotive to aerospace depends on high-quality metal casting, ensuring improved production efficiency. The direct pour system...

Introduction and Meaning : The term “Exothermic” refers to a chemical reaction or process that produces heat. Exothermic sleeves, is also known as exothermic riser sleeves or exothermic feeders, have revolutionized the casting process by providing controlled feeding of molten metal during solidification. Exothermic sleeves are consumable cylindrical tubes...

Introduction and Meaning In any area of electronic systems safety and efficiency are of uppermost importance. Insulation sleeves play a very vital role in protecting electronic components. Insulating sleeves are tubular pipe-like structures. Insulating sleeves are comprised of fiberglass, silica, ceramic or calcium- silicate yarns, silicone, rubber, PVC, polyolefin,...

Meaning and Introduction KAGALITE is natural pumice porous and contains volcanic rock called rhyolite. It is like a glass with a pale yellowish white and is found in the suburbs of Kanazawa City, Ishikawa prefecture in Japan. Kegalite is obtained from naturally occurring minerals. Kagalite has gained prominence in...