Brief introduction on Insulating Sleeves

Introduction and Meaning

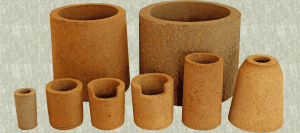

In any area of electronic systems safety and efficiency are of uppermost importance. Insulation

sleeves play a very vital role in protecting electronic components. Insulating sleeves are tubular

pipe-like structures. Insulating sleeves are comprised of fiberglass, silica, ceramic or calcium-

silicate yarns, silicone, rubber, PVC, polyolefin, and heat-shrinkable materials. It provides an

uninterrupted electric power supply. It protects from loss of power supply due to leakage or any

environmental hazards.

Insulating Sleeves category:

Heat-Shrinkable Sleeves: Heat-shrinkable sleeves create a tight and secure seal around the

electrical component when exposed to heat. Insulating sleeves provide excellent electrical

insulation and mechanical protection. It is popular in cable splicing, wire bundling, and

connector insulation.

Fiberglass Sleeves: Fiberglass sleeves are braided from woven fiberglass materials, covered with

a high-temperature resin. These sleeves protect hydraulic and electrical lines, cables, or wiring

from high temperatures. It is highly resistant to heat, erosion, and chemicals. These sleeves are

perfect for applications in high-temperature environments.

Silicone Rubber Sleeves: They are commonly used, in industries for applications where thermal

stability and moisture resistance are essential, such as electronic devices and industrial

machinery. Silicone rubber sleeves offer excellent flexibility and high-temperature resistance.

Polyolefin Sleeves: It is heat shrink sleeving Polyolefin sleeves provide good electrical

insulation and mechanical protection. They are widely used in cable and wire insulation,

offering resistance to abrasion and chemicals.

Applications and use of Insulating Sleeves:

Electrical Wiring and Cables: Insulating sleeves are mostly used to protect electrical

wires and cables, preventing contact with conductive surfaces and reducing the risk of

electrical hazards.

Electronic Components: In electronic devices and components such as cables, connectors,

switches, and terminals,insulating sleeves provide a protective barrier to ensure safe and reliable operation.

Motors and Transformers: Insulating sleeves are utilized in motors and transformers to

insulate electrical windings and protect against short circuits and electrical breakdowns.

Automotive Industry: In automobiles, insulating sleeves are crucial for protecting electrical

connections and harnesses, ensuring the safe and efficient operation of various electrical

systems.

Industrial Machinery: Insulating sleeves are used in industrial equipment to provide electrical

insulation, safeguarding workers and machinery from electrical accidents.

Benefits of Insulating Sleeves:

Electrical Safety: The primary benefit of insulating sleeves is enhancing electrical safety by

preventing accidental contact with live electrical components. This reduces the risk of

electrical shocks and electrical fires.

Enhanced Electrical Performance: Insulating sleeves provide a reliable barrier against

electrical currents, ensuring consistent and reliable electrical performance, reducing the risk

of electrical failures or malfunctions.

Mechanical Protection: Insulating sleeves offer mechanical protection to electrical

components, safeguarding them from physical damage due to abrasion, impact, or

environmental factors.

Temperature Resistance: Depending on the material used, insulating sleeves can provide

excellent resistance to high and low temperatures, ensuring performance in a wide range of

operating conditions.

Chemical and Moisture Resistance: Certain types of insulating sleeves exhibit resistance to

chemicals and moisture, making them suitable for harsh or corrosive environments.

Conclusion:

Insulating sleeves are indispensable components in electrical and electronic applications,

ensuring electrical safety, reliable performance, and protection against various environmental

factors. SSKIPL is the manufacturer of insulating sleeves in Pune, India.With various types of insulating sleeves available, each tailored to specific requirements,

they have become essential elements in industries ranging from automotive and manufacturing

to aerospace and electronics. As technology continues to advance, insulating sleeves will evolve,

offering even more specialized solutions to meet the evolving needs of electrical systems and

devices.