S. S. KHARDEKAR INDIA PVT. LTD.

Diecoats

DIECOAT 6 PASTE

PRODUCT:

Diecoat -6 paste use in pressure die casting.

DESCRIPTION :

Diecoat -6 paste product contains special lubricating additives. They are ready to use sprayable liquids or to be diluted with solvent. It is recommended for Shiny Finish.

INFORMATION :

- 1. Prevention of soldering.

- 2. Lubrication of die faces.

- 3. Protection to die faces.

- 4. Production casting with good surface finish & without stains.

PHYSICAL PROPERTIES :

- Color: Silver

- Appearance: Paste

- Sp.Gravity @ 30oC(diluted) : 0.95 to 1.00

STANDARD PACKING:

20kg/5kg Plastic Bucket.

SHELF LIFE:

6 Months from date of manufacture.

STORAGE AND HANDLING :

The product should be stored at room temperature under roof and away from direct sunlight, heat and moisture.

DIECOAT 22

DESCRIPTION :

DIECOAT -22 is a special purpose conductive coating for use in gravity die casting applications. This coating is mainly a graphite water based coating having high refractoriness with excellent conducting characteristics. Because of non –wetting nature & high temperature lubricity of graphite ,molten metal does not stick to the die and the solidified casting gets easily ejected .Diecoat -22 is specially formulated to satisfy environmental consideration in respect of emitted fumes ,low toxicity and minimum fire hazard.

HOW TO USE :

DIECOAT -22 is normally available as a pasty liquid .The coating is suitable for both swabbing and spraying applications .Depending upon the type of application selected the coating has to be diluted with sufficient quantity of water mixed thoroughly and then swab/sprayed.The coating should swabbed/sprayed on a hot die .Care should be taken to ensure that excessive coating is not deposited in pockets and deep corners on the die as this could lead to casting defects.

INDICATIVE SPECIFICATIONS :

|

PROPERTY |

PARAMETER |

|---|---|

|

Appearances |

Black colour water based paint. |

|

Specific gravity(as it is) |

1.30 to 1.50 |

|

Dilution |

1:1 |

|

Specific gravity (dil.) |

1.12 to 1.20 |

STANDARD PACKING :

20 kg Plastic Bucket .

SHELF LIFE :

6 Months from date of manufacture.

STORAGE AND HANDLING :

The product should be stored at room temp.under roof and away from direct sunlight & moisture .

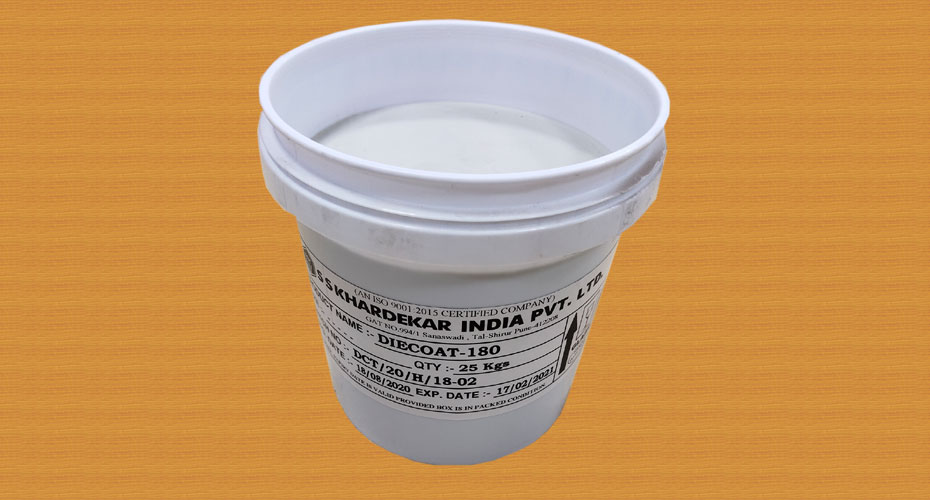

DIECOAT 180

PRODUCT :

Diecoat -180is an insulating coating for the protection of die & core faces and to control the rate of solidification gravity die casting.

FUNCTION :

In GDC &LPDC,Casting are produced with large /thinner sectioned aluminium alloys.When hot metal (aluminium alloy at 720 C )in cast into die (at 250C) the rate of heat extraction from the metal will be high & as a consequence fluidity of the cast metal will be reduces .Correct use of an insulating coating can control the rate of heat extraction in various parts of the die and so retain fluidity as well as provides a desirable directional solidification pattern in the casting.

ADVANTAGES :

- Easy release of casting.

- Better surface finish of casting.

- Easy filling of die-cavity.

- Economical.

APPLICATION:

Dilute the coating with soft water in the ratio 1:1 (product :water )mix uniformly and apply coating by spraying.The application of the coating is various from very thin where maximum chilling is required and thick on runners and feeders ,thin cast sections etc.Spray the diluted coating on to the die and core faces using a good atomizing gun.The die temperature should be between 120 -200 C so that the spray hits and dries quickly without running.Then re-heated the die to normal working temperature before casting metal.

PHYSICAL PROPERTIES:

- Color: Off White.

- Appearances: Paste .

- Sp.Gravity @30C: 1.30 to 1.50.

STANDARD PACKING :

20 kg Plastic Bucket .

SHELF LIFE :

6 Months from date of manufacture.

STORAGE & HANDLING :

The product should be stored at room temp..under roof and away from direct sunlight & moisture .