An ISO 9001:2015 Certified Company.

S. S. KHARDEKAR INDIA PVT. LTD.

WHAT WE SERVE

OUR PRODUCTS

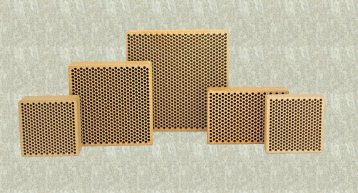

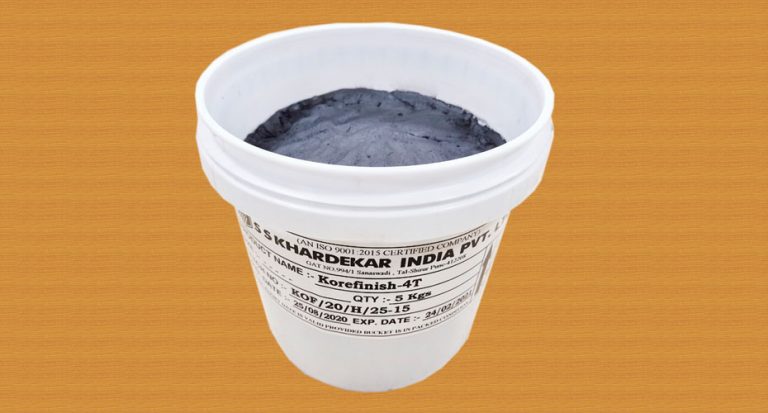

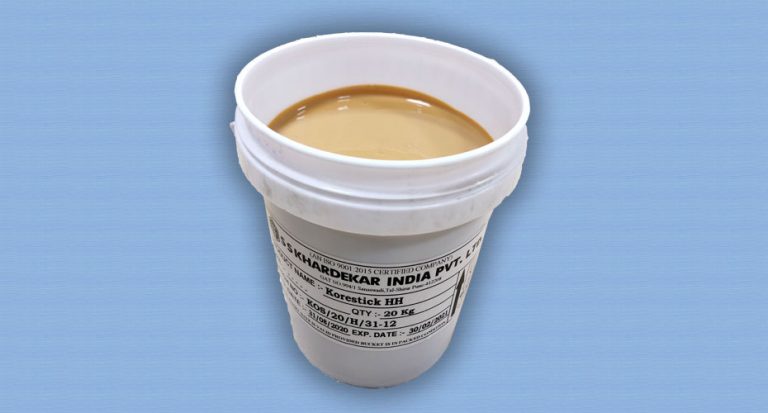

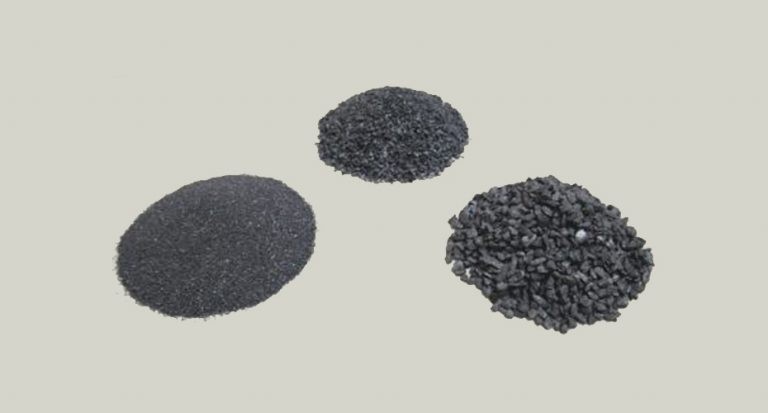

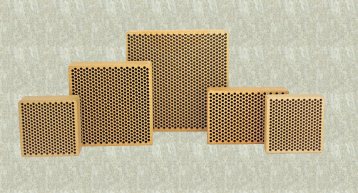

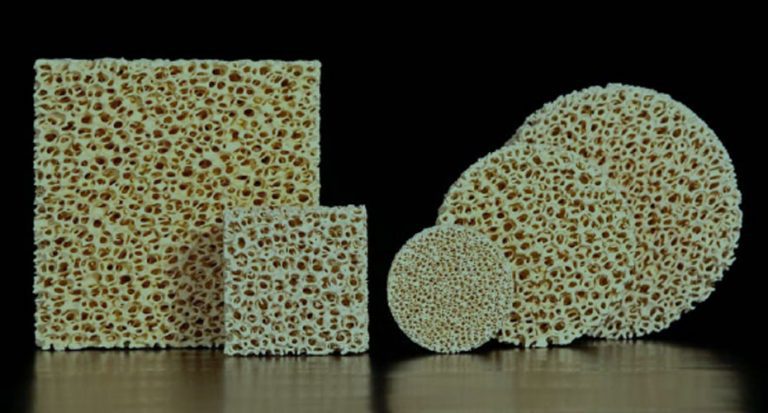

Exclusive Manufacturer and Suppliers of Insulating, Exothermic, High Density Sleeves, Direct Pour System, Mould & Core Coatings, Korestick, Mould Sealing Rope, Slag Coagulant, Kagalite K-2M, Alloy Inoculants, FeSiMg, Lanik Ceramic Foam Filters (VUKOPOR), Ceramic Filters, Parting Agent (W&K), Chilling Compound (Chromite Sand), Hot Tops, Tundish Boards, Hot Topping Compound and other products.

High Quality Foundry Products

SSKIPL

S. S. KHARDEKAR INDIA PVT. LTD. is an ISO 9001:2015 certified company founded in 2014 & engaged in manufacturing of various foundry products. "Within the span of Just 3 months, Our Company clearly recommended for the Certification of ISO 9001:2008, dated. 10th June 2015 & Recently, Our Company certified as ISO 9001:2015, dated.11th June 2017."

The company is having manufacturing unit at Gat No. 994/1, Sanaswadi, Tal – Shirur, Nareshwar Temple Road, Pune- 412 208. We are one of the leading manufacturer & supplier of wide range of Foundry products like Insulating Sleeves, Exothermic Sleeves, High Density Sleeves, Direct Pour System, Mould & Core Coatings, Korestick, Mould Sealing Rope, Slag Coagulant, Inoculants, FeSiMg, Hot Tops, Tundish Board, Laddle Board, HTC, APC, Lanik Ceramic Foam Filters (VUKOPOR) & Ceramic Filters etc.

In Co-operation with company Lanik Ceramic Foam Filters India Pvt. Ltd. & Keramtech s.r.o; we are supplying ceramic foam filters (VUKOPOR) & ceramic filters respectively.

Watch Our Videos

Blogs

Certifications

Reviews

Mr A N Kulkarni

SSKIPL has become the big name in the foundry Industry, in the Domestic and Export Market, because of their Product quality and Range in the products and working style. They work together with the customer for developing the products in time with low cost.

Mr V K Purohit

SSKIPL is a classic example of engineering a startup in India. It is competing with the Multinational brands since the birth oF the startup. Not only the cost, they are focusing on the customer satisfaction and the quality of the product.

Mr Petr Bohacek

We share a Decade old successful Collaboration with SSKIPL. We really appreciate significant growth in Indian market. We are focusing on customer satisfaction high quality products, following with technical support and service. We will carry on team collaboration and we will make sure we grow together.

Piyush Goswami

Harun Pathan

Ranjit Singh