S. S. KHARDEKAR INDIA PVT. LTD.

Inocul - Inoculant For Cast Iron

INOCUL - INOCULANT FOR CAST IRON

DESCRIPTION :

INOCUL is a product in granular form used as an inoculants for treatment of cast iron metal in ladle. When the molten cast iron is treated with INOCUL then it enhances reduction in chill, improvement in mechanical properties & machinability.

Inoculation is useful for the production of sound casting with uniform mechanical properties throughout the section.

METHOD OF APPLICATION :

INOCUL should be added to the clean molten metal. The best way of inoculation is to add INOCUL in the stream of metal as late as possible. Addition rate is most important since it is harmful to over-inoculate as well as to under inoculate. Over inoculation increases shrinkage and porosity in susceptible casting

BENEFITS :

- Reduction in Chill: Effect of inoculation is generally checked by chill/wedge test and tensile test piece. Chilling tendency is assessed by fracturing and measuring the width at a point where chill ceases. Un-inoculated flake graphite iron, especially those with low carbon equivalent are more prone to chill in thin sections, corners, sharp edges etc. INOCUL treatment reduces chill tendency.

- Promotes A type Graphite: Un-inoculated iron (with low carbon equivalent) is likely to contain under cooled graphite known as ‘D’ and ‘E’ type graphite. Under-cooled graphite affects the strength and machining properties. When molten metal is treated with INOCUL, the inoculation effect will eliminate under-cooled graphite and promote formation of ‘A’ type graphite to give better mechanical properties.

- Enhances Microstructure: Un-inoculated cast iron many times show, to a great extent, differences in graphite structure and ratio of Ferrite to Pearlite, between thin and thick section. Thin sections tend to contain fine graphite and free ferrite which reduces tensile strength. Thick sections tend to have coarse graphite which also reduces tensile strength. INOCUL treatment ensures uniform graphite structure and promotes formation of pearlite and hence

TYPES OF INOCUL :

The choice of grade of inoculants will depend on the metal composition, section thickness of casting, charging materials, melting temperature, and also ladle size etc.

Some of the grades are given below…

- INOCUL SB-5

- INOCUL SR

INOCUL SB-5

It is a highly effective inoculants based on ferrosilicon for grey and ductile cast iron. The elements barium, aluminium and calcium give the alloy an excellent inoculation effect over a wide range of applications. It is used for Grey Cast Iron & S. G. Iron.

CHEMICAL COMPOSITION :

Si :- 65-70%, Ba :- 2-2.5%, Ca :- 1.0-1.5%, Al :- 1.0-1.5%.

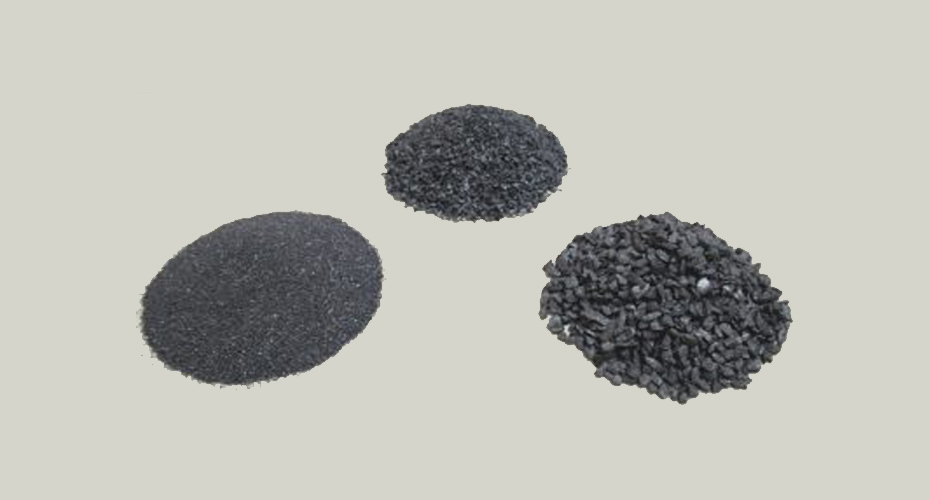

GRAIN SIZES :

It is available in grain size 1-3mm, 3-6mm & 0.2-0.7mm.

ADDITION RATE :

0.3-0.4% for ladle inoculation & 0.05% for Mould Inoculation.

SUGGESTIONS FOR ACHIEVING BETTER RESULTS :

- INOCUL should be stored in a dry place.

- Briefly stir the inoculated iron.

- Do not inoculate cold iron.

- Add inoculants only after removal of slag.

- Grey cast iron responds more favorably to inoculation if its sulphur content is in the range of 0.05-0.15% provided adequate Manganese is present to prevent formation of iron sulphide.

MODE OF STORAGE :

Keep in dry place and away from moisture.

SHELF LIFE :

One year from date of manufacture.

MODE OF PACKING :

25 kg paper bags.

INOCUL SR

It is highly effective, FeSi 75- based inoculant for Grey Cast Iron & ductile iron with a very low Aluminium & Calcium content. The inoculation effect is achieved through the Strontium content of the alloy. Using INOCUL SR in the production of ductile iron can be particularly effective when products with low Calcium & Rare Earth contents are used in the smelting, desulphurization & treatment process. It is also especially used for Cylinder Heads & Block Castings

CHEMICAL COMPOSITION :

Si :- 72-77%, Sr :- 0.8 – 1.2%, Al :- < 0.1 % , Ca :- < 0.1%

GRAIN SIZES :

It is available in 1-3mm, 3-6mm & 0.2-0.7mm.

ADDITION RATE :

0.05-0.25% for ladle inoculation & 0.05% for Mould Inoculation.

SUGGESTIONS FOR ACHIEVING BETTER RESULTS :

- INOCUL should be stored in a dry place.

- Briefly stir the inoculated iron.

- Do not inoculate cold iron.

- Add inoculants only after removal of slag.

- Grey cast iron responds more favorably to inoculation if its sulphur content is in the range of 0.05-0.15% provided adequate Manganese is present to prevent formation of iron sulphide.

MODE OF STORAGE :

Keep in dry place and away from moisture.

SHELF LIFE :

One year from date of manufacture.

MODE OF PACKING:

25 kg paper bags.

NODULARIZER

CHEMICIAL COMPOSITION

Selection of FeSiMg according to grain size & % Mg.

|

Sr. No. |

Grain size |

Chemical Composition |

Addition rate (% of liquid metal) |

Pack size |

|---|---|---|---|---|

|

1

|

5-15mm

|

Si :- 44-48%, Mg :- 5.0-7.0%, Re :- 0.8-1.2%, Ca :- 0.8-1.2%, Al :- 1.0% MAX., MgO :- 0.7% MAX. |

1.2-1.3%

|

50 Kg

|

|

2

|

10-25mm

|

Si :- 44-48%, Mg :- 8.0-10.0% & 6-8%, Re :- 0.8-1.2%, Ca :- 0.8-1.2%, Al :- 1.0% MAX., MgO: - 0.7% MAX. |

0.8-0.9%

|

25 Kg

|

|

3

|

15-25mm

|

Si :- 44-48%, Mg :- 6.0-8.0%, Re :- 0.8-1.2%, Ca :- 0.8-1.2%, Al :- 1.0% MAX., MgO- 0.7% MAX. |

1.0-1.1%

|

50 Kg

|

|

Sr. No. |

Grain size |

Chemical Composition |

Addition rate (% of liquid metal) |

Pack size |

|---|---|---|---|---|

|

1

|

5-15mm

|

Si :- 44-48%, Mg :- 5.0-7.0%, Re :- 0.8-1.2%, Ca :- 0.8-1.2%, Al :- 1.0% MAX., MgO :- 0.7% MAX. |

1.2-1.3%

|

50 Kg

|

|

2

|

10-25mm

|

Si :- 44-48%, Mg :- 8.0-10.0% & 6-8%, Re :- 0.8-1.2%, Ca :- 0.8-1.2%, Al :- 1.0% MAX., MgO: - 0.7% MAX. |

0.8-0.9%

|

25 Kg

|

|

3

|

15-25mm

|

Si :- 44-48%, Mg :- 6.0-8.0%, Re :- 0.8-1.2%, Ca :- 0.8-1.2%, Al :- 1.0% MAX., MgO- 0.7% MAX. |

1.0-1.1%

|

50 Kg

|