S. S. KHARDEKAR INDIA PVT. LTD.

Auxiliary Products

MOULD SEALING ROPE

DESCRIPTION :

MOULD SEALING ROPE is used for sealing the parting line of two moulding boxes. It is available in various sizes i.e. in diameters i.e. 4mm, 6mm, 9mm & 12mm.

APPLICATION :

MOULD SEALING ROPE is placed at the parting line of the drag half moulding box over the periphery and then cope half is placed over it.

- MOULD SEALING ROPE is friendly user.

- It eliminates the old conventional fireclay, mud and also saves time.

- The consistency of the MOULD SEALING ROPE is such that it does not crack or break even after twisting. This ensures flawless sealing of the parting line.

- MOULD SEALING ROPE takes the exact shape of the cavity when cope half is placed and thus seals the parting line effectively

- MOULD SEALING ROPE becomes hard when the casting is poured and evolves minimum gas.

- It is refractory and plasticizer base.

SHELF LIFE :

Six months from the date of packing.

SLAG COAGULANT

DESCRIPTION :

SALIENT FEATURES:

CHILLING COMPOUND is the best Chromite Sand media for chilling metal. It has the ability to draw heat from the molten metal allowing the metal to skin over faster and minimizing sand burn on. Thus will help to reduce casting rejections.

- MOULD SEALING ROPE is friendly user.

- It eliminates the old conventional fireclay, mud and also saves time.

- The consistency of the MOULD SEALING ROPE is such that it does not crack or break even after twisting. This ensures flawless sealing of the parting line.

- MOULD SEALING ROPE takes the exact shape of the cavity when cope half is placed and thus seals the parting line effectively

- MOULD SEALING ROPE becomes hard when the casting is poured and evolves minimum gas.

- It is refractory and plasticizer base.

PHYSICAL PROPERTIES :

The Higher the Expansion, better the Slag Coagulation property. Expansion of SLAG COAGULANT is 18-24 CC.

BENEFITS :

Due to higher Expansion (18-24 cc),

- Addition rate is 0.15-0.25% of liquid metal wt.

- It improves the quality of Slag Coagulation & will help in minimizing rejection due to slag inclusion in house as well as after machining the castings.

- Due to higher quality of Slag Coagulation, It increases the fluidity of liquid metal & reduces the temperature drop of liquid metal during pouring.

SALIENT FEATURES :

Presence of extremely low or negligible fines helps to maintain clean atmosphere surrounding the furnace.

STORAGE PRACTICE:

Storage in Cool & Dry place.

SHELF LIFE :

12 months from the date of manufacturing.

PACK SIZE :

50 Kg. HDPE Bags.

CHILLING COMPOUND - CHROMITE SAND

DESCRIPTION :

PHENOMENON OF EXPANSION :

When Slag Coagulant comes in contact with the metal, it reacts with the slag & starts coagulation i.e. formation of spongy agglomeration. The Coagulation depends on Expansion of Granules.

CHEMICAL COMPOSITION :

Cr2O3: 45-47%, SiO2: 1% Max., Fe2O3: 27-29%, Al2O3: 14.5%, CaO: 0.18 typical, Max 0.2%,

MgO: 10.2 Typical & max. 11%, TiO2: 0.69%, V2O5: 0.34%, P: 0.0029%, S: 0.0029%, Cr:Fe ratio: 1.58:1

PHYSICAL PROPERTIES :

Bulk density: 155-165 lbs/cu.ft

AFS No.: 40-50

ADVANTAGES:

- It is having 45-47% Chromic Oxide & max.1% Silica & offers higher chilling properties and reduces burn on sand.

- Turbidity should be less than 250 ppm reduces the amount of resin needed to maintain tensile strength & the permeability of the sand.

- An ADV at pH 7 <5 offers less molding sands work and higher tensile strengths.

- In a PUCB system, low ADV will offer the resin/sand mix to become more compact and offers high tensile strengths.

KAGALITE K-2M (JAPAN)

INTRODUCTION :

SSK has entered into joint venture with M/s KAGALITE KOGYO CO. LTD. JAPAN .

This product was developed especially for Highest Safety to Furnace operator.

SALIENT FEATURES :

Extremely Low density 0.80 – 0.85 g/cc which is 50-60% of the ordinary perlite.

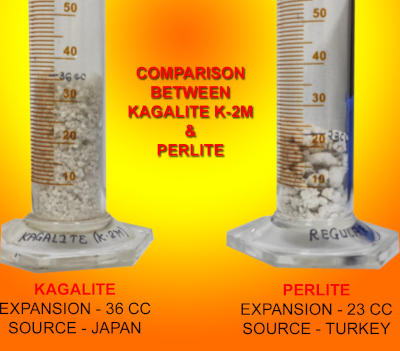

2) Expansion is 36cc against 23-24 cc of Ordinary perlite.

3) Addition rate is max 0.15% against 0.3-0.4% of perlite.

4) No spirting of metal results in high METAL cleanliness surrounding the furnace &

inside the plant.

5) Highest quality of Slag Coagulation & will help in minimizing rejection due to slag

inclusion at foundry as well as after machining stage.